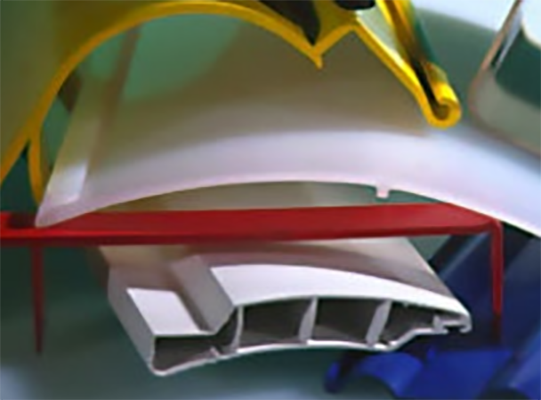

Since 1999, Valley Extrusions, a custom precision profile extruder that can handle 100 to 20,000 pieces an hour and regularly runs about 450 SKUs. The firm has been providing customers with the in-house R&D and tooling required to produce tag moldings and label holders as well as a wide range of parts and components for use in everything from track lighting to commercial refrigeration units and lens covers. Items range in size from one-inch square to 18 inches by 16 ft.

Vital Statistics

Valley Extrusions’ 35 employees run about 450 SKUs on the 12 extrusion lines in a 200,000 sq. ft. plant that also includes storage and warehousing space to accommodate raw materials, packaging and finished products.

Key Challenges

After many years with a heavily customized, widely used industry ERP for manufacturing, Valley Extrusions finally accepted the fact the software didn’t understand the plastics business and never would. As a result, Valley Extrusions didn’t have immediate access to the real-time data that could allow them to further improve efficiency and profitability while accomplishing their goal of delivering even better customer service. Valley Extrusions needed a plastics-specific ERP that could track and flag minimum inventory levels (raw materials, finished products) to improve planning and delivery and manage restocking and customer blanket orders. They also needed an ERP that could access and use the quality, detailed, just-in-time data required for the accurate, actionable reports needed to strategically operate and manage the business.

Why CyFrame?

After searching for the right system to drive value in their operations, a Google search led Valley Extrusions to CyFrame. Conversations about internal processes and leveraging real time data in conjunction with CyFrame’s demos proved its off-the-shelf software had been developed by people who really understood the plastics industry specifically for companies that manufactured plastic products . The hands-on approach to mapping their critical objectives and understanding the key opportunities for a quick payback showed Valley Extrusions that the CyFrame ERP could handle the crucial data, such as “pounds per minute/hour” and “feet per second”, that was the starting point for reports that determined cost and profitability on a job-by-job basis and seamlessly generated monthly and even weekly P&Ls.

Solution

In March 2014, Valley Extrusions went live with CyFrame’s ERP for Profile Extrusion.

Benefits

Thanks to CyFrame’s ERP, Valley Extrusions’ senior executives and managers now know which jobs are the most profitable and why and when and where price increases may be warranted. They’re also able to identify and troubleshoot problematic tools and dies before significant problems arise to ensure the quality and volumes its customer expect on schedule. As importantly, key employees readily trust CyFrame’s ERP to automatically create 40 work orders in just 10 minutes versus the mind-numbing four hours previously required to do it manually.