Profitability Reporting

Enabling real-time profitability with PLC tracking

CyFrame’s shop floor data acquisition software specifically for plastics processors includes an optional integrated PLC module to tracks: scrap, downtime and production efficiency. This keeps you up to date on your live operations. Grow beyond the archaic method of recompiling data from the end of the month reporting to understand your profitability. Run up to the minute production reporting at any time of the day, from any location and get the information you need when you need it so you can start managing the future of your business with today’s information.

The power to capture accurate results in real-time

Consider connecting all your machines via a Master PLC controller and activate the capability to track your true up to the minute results against the standard expected performance targets defined in all your finished products.

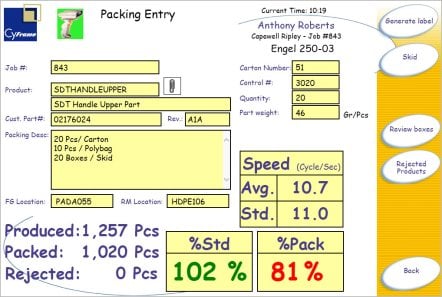

Scanning finished products directly on the production line avoids having to manually capture and then later re-enter shift or daily results on a separate screen or system while keeping raw material and finished good inventory up-to-date. For that purpose, an uncomplicated, basic touch-screen / bar-code interface can be installed at each machine, work center or a central location on the shop floor.

Monitor production profitability

CyFrame does an excellent job at monitoring your production profitability. With this integrated solution you will understand where you can improve profitability based on concrete data such as:

Production performance – Actual vs. Standard</h3?

A complete set of profitability drill-down reports state what your overall profitability is for any given customer, product or work order.

These sets of reports will display tell you your production time efficiency, Production yield against rejects, what the rejects were and if the product weight was on target.

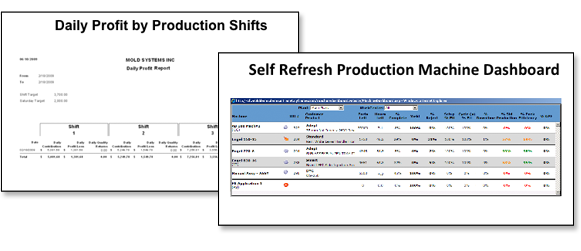

Daily Production Profit Contribution

In addition to tracking and achieving daily work order performance goals another series of reports computes the daily shift total profit target. Excluding any production rejects, these reports inform the business on how each shift has contributed to the overall profit target. This will put into perspective whether if the daily production was profitable and which shift contributed the most.

Price List Profitability

Have your customers maintained the agreed upon purchase level?

Making shorter runs than anticipated may be less profitable and contribute less profit than expected. This detailed report shows the production efficiency and reject levels for each part of the price list and make evident the impact of freight on overall customer profitability.