It’s 2025. If you’re managing a plastics processing business, you probably already know that ERP software can help you run leaner, smarter, and more profitably.

It’s 2025. If you’re managing a plastics processing business, you probably already know that ERP software can help you run leaner, smarter, and more profitably.

But here’s the thing: most ERP projects don’t succeed. Especially when the system wasn’t designed for your industry.

Generic ERP platforms often seem affordable—until you realize they require endless customization just to reflect the basics of your operations. Timelines drag. Budgets swell. And the promised ROI becomes a moving target.

At CyFrame, we took a different approach. Our ERP is built exclusively for plastics processors, with everything you need—right out of the box. That means faster deployment, smoother adoption, and results you can measure on the floor and on your balance sheet.

Let’s break down why that makes all the difference.

Why One-Size-Fits-All ERP Doesn’t Work for Plastics

Why One-Size-Fits-All ERP Doesn’t Work for Plastics

Plastics manufacturing isn’t just “manufacturing.” Whether you’re doing injection molding, extrusion, blow molding, or recycling, your process has unique realities: Tooling related production / cycle times, recipes and alternative recipes, scrap rates, setup times, tooling changeover regrind, —you name it.

Most ERPs don’t speak that language. So you’re left translating your workflows into someone else’s framework—at great expense and risk.

CyFrame doesn’t need translation. Our platform was built around best practice plastics-specific workflows from the start. That means you don’t have to reinvent the wheel—we’ve already built it for you and it’s spinning at velocity.

Faster Implementation. Less Headache. No Risk. Quicker ROI.

When your ERP isn’t a good fit, every meeting becomes a workaround. Every training session turns into damage control. And every change requires custom development.

With CyFrame, the system already matches how you natively operate. So implementation is faster, training is easier, and the results start showing up sooner.

In fact, most of our clients are live in a fraction of the time it takes with a generic platform—because our software already knows your business.

Real ROI Starts with Day-One Value

ERP should pay for itself by improving efficiency, eliminating errors, and helping you to closely monitor your costing. But if it takes a year just to get basic functionality, the return feels far away.

With CyFrame, you don’t wait.

From day one, you’re getting:

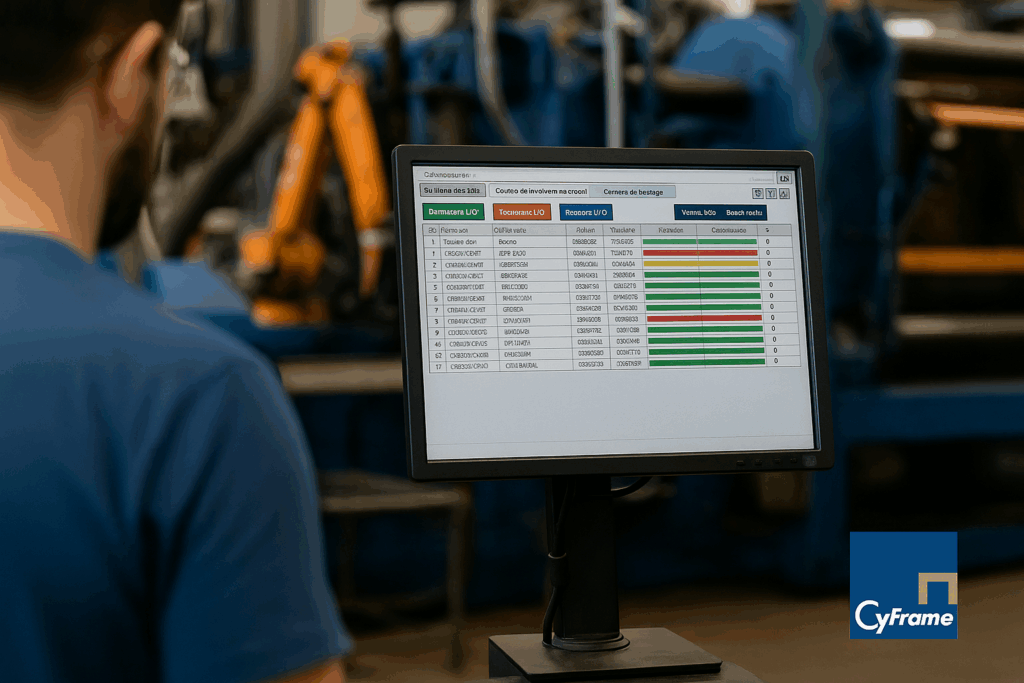

- Real-time production visibility

- Live MRP

- Reliable costing

- Optimized planning

- Better quoting

These aren’t nice-to-haves—they’re profit levers. The faster your system works, the faster you can scale with confidence.

Our Advisors Speak Plastics—Not Just Software

Most ERP vendors are software-first. That’s fine—unless you need help making decisions rooted in plastics operations.

At CyFrame, our team is different. We don’t just configure software—we advise based on decades of experience in plastics processing. We’ve helped hundreds of processors reduce downtime, optimize production, and improve cost control.

That’s why our implementation isn’t just fast—it’s strategic. We won’t just ask what you want. We’ll help you uncover what will actually move the needle.

Clarity Over Complexity: One Platform for Everything

Trying to bolt together a generic ERP with spreadsheets, plugins, and third-party tools? That’s a recipe for confusion, risk, and maintenance nightmares.

CyFrame is one unified system—purpose-built for plastics.

From production to inventory, scheduling to costing, everything lives under one roof. That means no more fragile integrations and no more wondering if your numbers are right.

Not Ready Yet? That’s Okay—But Don’t Settle for the Wrong Fit

If you’re considering a small “starter” ERP because your budget is tight, here’s our honest advice: save your money and stick with Excel and try to improve upon your manual controls—as long as you have solid manual controls in place.

Then, when your operations start getting too complex to manage manually, when critical items begin to fall between the cracks and you need to hire to fill them, that’s your signal. That’s when CyFrame becomes not just helpful, but essential.

And here’s what we suggest in the meantime: let us take a look at your operations. No pressure. No hard sell. We’ll show you where the bottlenecks are, where you’re losing profit, and where our system could make the biggest impact.

Let’s Make Your ERP Story a Success Story

ERP doesn’t have to be a gamble.

With CyFrame, you get a system designed from the ground up for plastics processors. No endless customization. No painful surprises. Just a clear path to better visibility, efficiency, and profit.

Start with an operational review. We’ll map out what’s holding you back—and show you what’s possible when the software actually fits your business.